|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

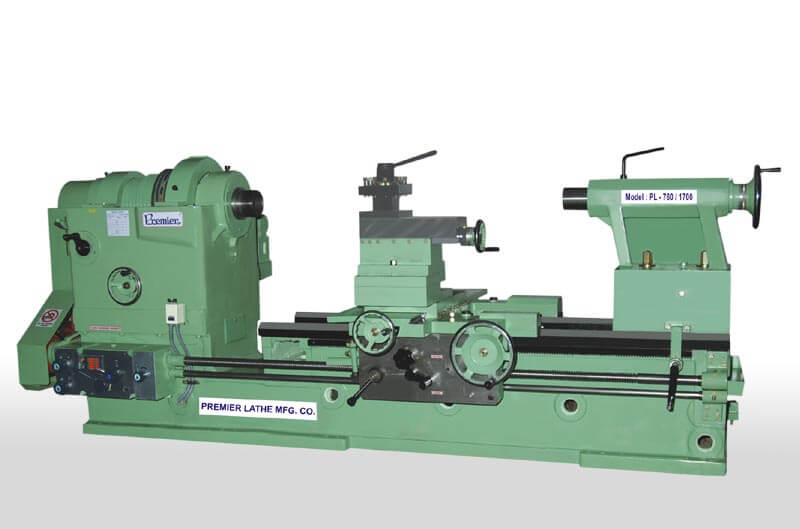

Special Features

- Induction harden bed ways.

- Bed Is Made From High Quality Cast Iron and Strictly Inspected With Micro Level & Straight Edge.

- Single Piece Plano Type Solid Bed.

- Turcite – B Coated In Saddle & Cross Slide Guideways.

- Heavy Duty Headstock, In Which Spindle Runs On One Taper Roller Bearing and One Cylindrical Roller Bearing In

Front & - One Taper Roller Bearing At Rear Side.

- Headstock Spindle Is Made From High Tensile Steel Duly Hardened & Ground.

- Double Shaft Norton Gear Box & Apron, Which Is Totally Enclosed Oil Bath System With Lever Type Arrangement for

- Automatic Feeds.

- Sliding Type Counter Assembly For Easy Changing Of V-belt From One Step To Another Step.

- Tail Stock Spindle Is Hardened & Ground, Made From Alloy Steel.

- Meticulous Care is Taken in Selecting The Right Raw Material For Every Component. Each & Every Component Is

Passed - Through Strict Quality Control.

- Machine Accuracy Is Tested As Per Is : 1878 (part – I) 1971.

Standard Accessories:

Chuck Back Plate, Tool Post Spanner, Motor Pulley, Motor Channel, Change Gear Set, Fix Spanner Set, Allen Key Set & Oil Cane.

Optional Accessories:

Face Plate, Steady Rest, Follow Rest, Carrier Plate, Rear Tool Post With Extended Cross Slide, Coolant Pump with Tank And Fittings, Taper Turning Attachment, Machine Lamp, Electric Motor, R/F Switch, Motor V- Belt, Dog Chuck, True Chuck, Customized Center Height of Machine.